TPEE : Thermoplast polyester elastomer

TPEE: Thermoplastic Polyester Elastomer

CAS NO.:25038-74-8

Capacity: 10KT/Year

TPEE (Thermoplastic Polyester Elastomer) is a block copolymer composed of alternating hard segments (typically PBT—polybutylene terephthalate) and soft segments (usually polyether or polyester diols). This unique structure gives TPEE a rubber-like flexibility combined with thermoplastic processability and excellent mechanical strength.

Specification

ITEM | TEST | UNIT | GRADE | |||||

TH3040 | TH3140 | TH3045 | TH3145 | TH3050 | TH3150 | |||

Hardness | GBT531 | shore D | 40±2 | 40±2 | 45±2 | 45±2 | 50±3 | 50±3 |

Melt Index (2.16kg) | ISO1133-1-2011 | g/10min | 8-15 | 16-30 | 8-15 | 16-30 | 8-15 | 16-30 |

℃ | 230 | 230 | 230 | 230 | 230 | 230 | ||

Tensile Strength | GB/T528 | Mpa | ≥18 | ≥15 | ≥22 | ≥20 | ≥28 | ≥24 |

Tensile Elongation | GB/T528 | % | ≥800 | ≥600 | ≥750 | ≥550 | ≥700 | ≥600 |

Flexural Modulus | ISO178-2010-A | Mpa | ≥75 | ≥60 | ≥80 | ≥70 | ≥90 | ≥80 |

Tearing Strength | ISO 034-1-2015-B | KN/m | ≥120 | ≥100 | ≥125 | ≥110 | ≥130 | ≥120 |

Vicat Softening Point | ISO306-2013-A50 | ℃ | ≥130 | ≥140 | ≥140 | |||

Melting Point | ISO 11357-3-2001 | ℃ | 200±3 | 200±3 | 210±3 | 210±3 | 204±2 | 190±3 |

Brittle Temperature | ISO974-2000 | ℃ | -70 | -70 | -70 | |||

Specific Gravity | ISO 1183-1-2012 | g/cm3 | 1.125-1.145 | 1.130-1.155 | 1.150-1.190 | |||

ITEM | TESTMETHOD | UNIT | GRADE | |||||

TH3055 | TH3155 | TH3060 | TH3160 | TH3063 | TH3163 | |||

Hardness | GBT531 | shore D | 55±2 | 55±2 | 60±3 | 60±3 | 63±2 | 63±2 |

Melt Index (2.16kg) | ISO 1133-1-2011 | g/10min | 8-15 | 16-30 | 8-15 | 16-30 | 8-15 | 16-30 |

℃ | 230 | 230 | 230 | 230 | 230 | 230 | ||

Tensile Strength | GB/T528 | Mpa | ≥30 | ≥25 | ≥30 | ≥27 | ≥32 | ≥30 |

Tensile Elongation | GB/T528 | % | ≥550 | ≥400 | ≥400 | ≥400 | ≥550 | ≥500 |

Flexural Modulus | ISO 178-2010-A | Mpa | ≥160 | ≥140 | ≥180 | ≥160 | ≥250 | ≥200 |

Tearing Strength | ISO 034-1-2015-B | KN/m | ≥150 | ≥130 | ≥160 | ≥140 | ≥170 | ≥150 |

Vicat Softening Point A/50 | ISO 306-2013-A50 | ℃ | ≥160 | ≥160 | ≥180 | |||

Melting Point | ISO 11357-3-2001 | ℃ | 205±3 | 203±3 | 210±3 | 213±3 | 213±3 | |

Brittle Temperature | ISO974-2000 | ℃ | -70 | -60 | -60 | |||

Specific Gravity | ISO 1183-1-2012 | g/cm3 | 1.19 | 1.185- | 1.210-1.240 | 1.220-1.250 | ||

ITEM | TEST METHOD | UNIT | GRADE | |||

TH3068 | TH3168 | TH3072 | TH3172 | |||

Hardness | GBT531 | shore D | 68±3 | 68±3 | 72±2 | 72±2 |

Melt Index(2.16kg) | ISO 1133-1-2011 | g/10min | 10-15 | 16-30 | 10-15 | 16-30 |

℃ | 240 | 240 | 240 | 240 | ||

Tensile Strength | GB/T528 | Mpa | ≥33 | ≥31 | ≥35 | ≥33 |

Tensile Elongation | GB/T528 | % | ≥500 | ≥400 | ≥450 | ≥350 |

Flexural Modulus | ISO178-2010-A | Mpa | ≥300 | ≥250 | ≥500 | ≥350 |

Tearing Strength | ISO 034-1-2015-B | KN/m | ≥180 | ≥160 | ≥190 | ≥170 |

Vicat Softening Point A/50 | ISO 306-2013-A50 | ℃ | ≥180 | ≥180 | ||

Melting Point | ISO 11357-3-2001 | ℃ | 215±3 | 218±3 | ||

Brittle Temperature | ISO 974-2000 | ℃ | -60 | -50 | ||

Specific Gravity | ISO1183-1-2012 | g/cm3 | 1.240-1.260 | 1.250-1.280 | ||

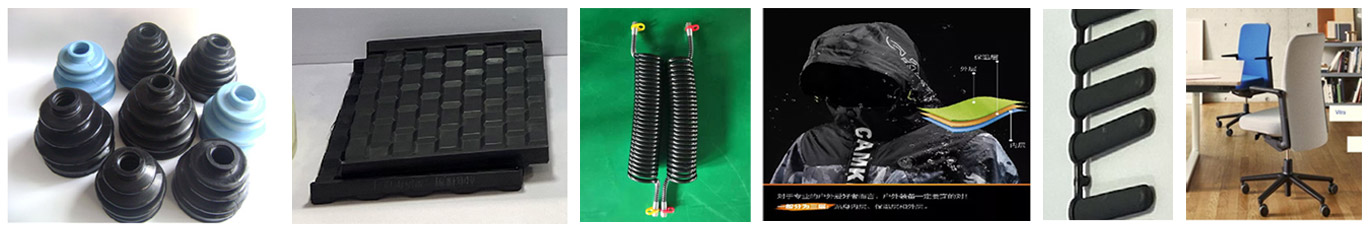

Product Application

CVJ Boots: TPEE have demonstrated excellent performance in terms of aging resistance, low-temperature toughness, fatigue resistance, medium resistance, and deformation resistance. These advantages make TPEE an ideal choice for manufacturing CVJ dust covers, which can effectively cope with harsh working environments and ensure that the transmission performance of universal joints is not affected.

Railway Pad:TPEE has good elasticity and high hardness, which can maintain good deformation rebound characteristics under severe impact, effectively absorb the impact force of train operation on track structure, and protect pillows and other parts.

Automobile Hanging Pipes:Compared to TPU, TPEE has better resilience and tensile strength, is more suitable for a wider temperature range, and adapts to the needs of trucks in different climatic conditions.

Outdoor Jacket Inner link:TPEE breathable material can be used as an inner liner for submachine jackets, with good breathability and filtration performance.

Router Antenna:Due to its excellent mechanical properties and resistance to bending, it can ensure that the optical fiber is not damaged (fiber optic connectors).

Elastic Fabric:Excellent rebound performance, comfortable flexible touch, and excellent wear resistance have good applications in elastic fabrics.

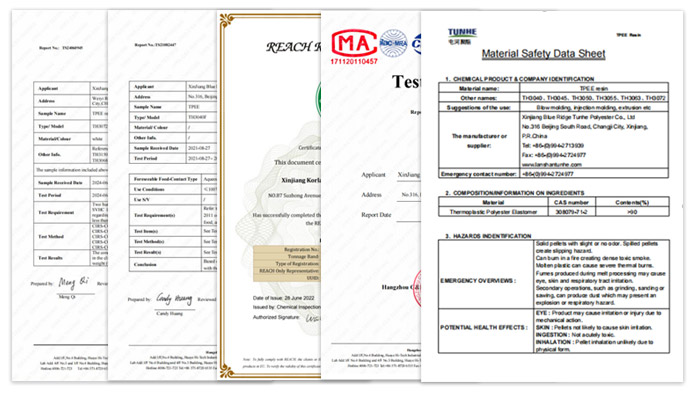

Certificates and Compliance

ROHS / SVHC / REACH Registration / Food Contact / MSDS